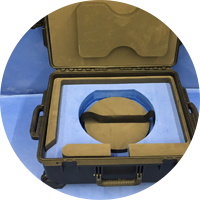

Cases and Custom Foam Inserts

When you have fragile and vital equipment to transport you need a case with foam inserts designed and engineered by MM Solutions. With us, you get over 30 years of technical expertise to help you choose the right case and foam insert that will perform best for shipping your product.

Our engineers start by calculating the cushion curves to ensure your equipment will be adequately protected and perform well for your transit requirements. Then our team works to configure your case for usability and enhanced presentation of your products. Finally, your cases are sent to manufacturing to have your design engineered foam inserts produced from the highest precision CNC cut materials and installed to the case.

Variety of Stock Foam Materials:

- Poly Ethylene (PE) (Ethafoam)

- Crosslink PE (XLPE)

- Polyurethane (PU)

- Anti-static and non-conductive foam

- Stratocell (PE foam – different cushion properties when compared to Ethafoam)

- Plastazote LD24FR (Flame Retardant Crosslink PE)

- Zote Foam (Azote and Zotek)

- Crosslink PE in 1.5#, 2#, 3#, 4#, 6#, 8#, 9#, 15# (colors may only be available up to 4# – all others are charcoal)

- Military spec foam A-A-59136, MIL-P-26514, PPP-C-1752

- Many other stock foams available

Cases and Foam Manufacturing

- CNC cut foam

- Foam, metal, plastic, and specialty materials

- Tested fabrication and fastening systems

- JIT deliveries available

- Short-run or high-volume production

- Lean manufacturing and continuous improvement processes

Custom Engineered Packaging

- CAD drawings for production quality management systems

- Foam designed for protection, function, and aesthetics

- Consistent quality guaranteed

- Cushion curves calculated for ultimate protection

- Optimize accessory configuration planning

- Reduce environmental effects on static stress curves

- Minimize vibration, buckling, and creep

- Dusting fragmentation and non-abrasive qualities

Foam Cushioning

- Engineered for ultimate protection

- Protection against shake, shock, and vibration

- Cushion curves calculated for product requirements

- Green reusable and recyclable options available

- Antistatic and non-conductive foams

- Polyurethane, polyethylene, and cross-link foams

- Zote Foam

- Stratocell

Shock, Drop, Vibration, and Environmental Testing

- Replicate the conditions of your shipment in a controlled environment to test your case and packaging

- Identify requirements of packaging

- Reduce and end product returns/freight damages

- Certified test to ISTA/ASTM standards

- Reports delivered with testing data

Military and Government Compliant Packaging

- Military spec foam A-A-59136, MIL-P-26514, PPP-C-1752

- MM Solutions manages all aspects of military spec packaging, inspection and shipping requirements

- Custom packaging per contract Mil-Spec; to include Military ship labels, pack lists, and WAWF Invoicing